septembre 30, 2021

90% off

As far as discounts go, 90% is a big one. You don’t even get that much of a cut off of Halloween chocolate in mid-November. But one of the things we’re proudest of with Stageline mobile stages is that they routinely cost 90% less to install and get ready than other traditional ground-support solutions.

The reasons are fairly simple. If you’re of a certain age, you grew up with Transformers. Most people get the basic idea of the Transformer toy—it’s one toy that with a few twists and turns, becomes another toy entirely. Stageline’s mobile stages aren’t quite like that, but they’re not really that different, either.  Above all, they’re best understood as machines deployed in a pre-engineered sequence, factory designed with only one purpose in mind: Safe Outdoor staging. And where that matters the most is when you remember that it only takes one person at a time to transform a transformer from one shape into another. In the same way, a Stageline stage really relies on one single operator to a few for most models to transform it from a truck trailer to a fully functioning stage with overhead rigging and PA supports, ready to welcome performers in record time.

Above all, they’re best understood as machines deployed in a pre-engineered sequence, factory designed with only one purpose in mind: Safe Outdoor staging. And where that matters the most is when you remember that it only takes one person at a time to transform a transformer from one shape into another. In the same way, a Stageline stage really relies on one single operator to a few for most models to transform it from a truck trailer to a fully functioning stage with overhead rigging and PA supports, ready to welcome performers in record time.

Time is money, indeed. But time is never as much money as when you’re paying for somebody else’s time. This, then, is how we’ve made it possible for you to save 90% of the costs you would have laid out to erect a ground-support stage. Traditional staging solutions require a team of between four and eight times as many workers, labouring for several more hours if not days as they build a structure bolt by bolt, pin by pin, wire by wire—and that’s before you have to hire the third-party engineer to certify the thing.

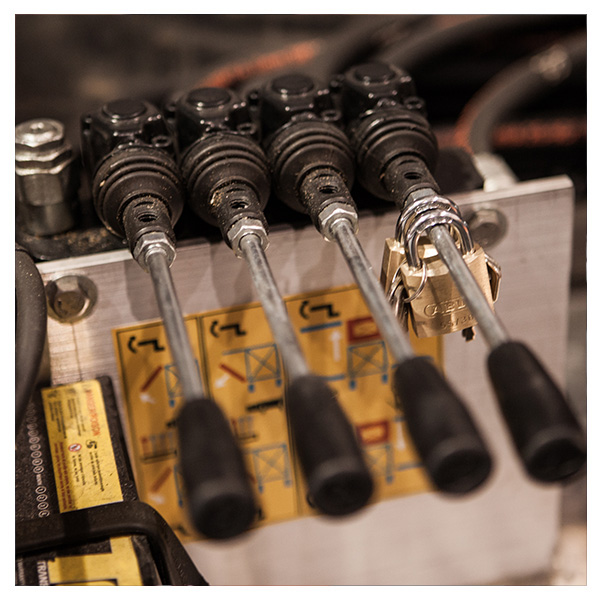

The experience of seeing a Stageline stage deployed is something a lot more graceful, a lot more orchestrated—you’ll forgive us if we say we see even a little bit of ballet in the deployment. But the fact is that all the hard work is done before the stage leaves the factory. What that means is that on site, all that’s left for the stage to do is to work its magic—which can take as little as one tech using joysticks, and raising the roof hydraulically at the touch of a button. With the exception of our SAM stages, there’s no need for external machinery or cranes at all, and even the SAMs, which only require a forklift, save you 90% compared to traditional solutions of the same size and capacity. Plus, before our stages leave the factory, they’re already engineer-certified, meaning you don’t even have to shell out for a on site engineer’s inspection.

For any stage of the same amount of surface, similar capacity, similar trim-height, it’s a no-brainer. The amount of manpower and man-hours required to make that surface usable is just always cheaper with Stageline. It’s easy enough to build a stage with zero rigging and wind resistance capacity—but where it gets tricky (and often dangerous) is when you rig the equipment and the roof in a live outdoor scenario. That’s why Stageline doesn’t take risks—every stage comes out of the factory with its purpose and identity built in. The Stageline identity is all about safety and reliability, every time—but it’s also about just as reliably saving you money.